Fives Pillard Deutschland GmbH

Fives Pillard Deutschland GmbH, 1957 until today

2013

PILLARD FEUERUNGEN GmbH changes its corporate identity to match the fives group and becomes Fives Pillard Deutschland GmbH.

2007

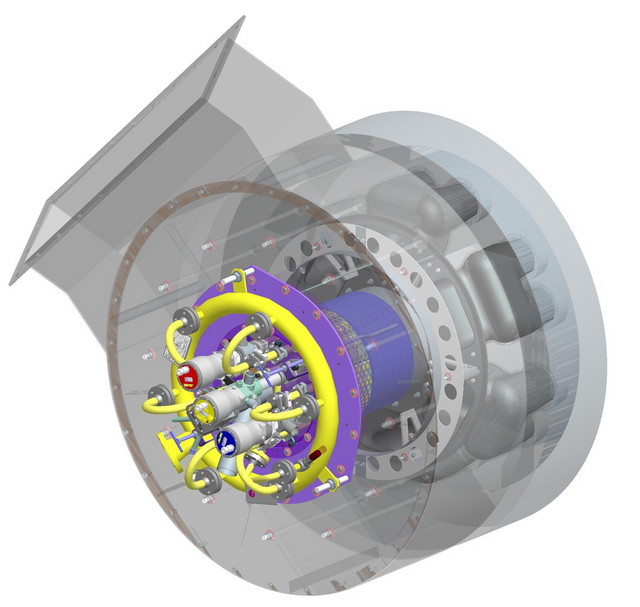

Pillard puts the new ROTAFLAM ® RV2 into operation in a German cement factory.

This newest achievement is specially developed for using the maximum quantity of solid alternative fuel.

The operating result from the first half of the year surpasses expectations. Using refused derived fuels (RDF) yields a thermal

output in excess of 70%, which in turn results better clinker quality and kiln operation when compared to using comparable primary fuels.

2003

At a customer presentation, “Pillard Aktuell”, Pillard Group presents its further developed rotary burner, ROTAFLAM ® WF, to an interested clientele.

This type of burner can be operated using up to 7 different liquid as well as solid alternative fuels at the same time. Substitution rates of up to

100 % are reached. Consequently, more than 50% of the full amount of alternative fuels in operation can be solid.

2001

Pillard Feuerungen GmbH converts the entire old plant at the cement factory in Yanbu, Saudi Arabia from using crude oil to heavy fuel oil.

The project is completed to the fullest satisfaction of the customer and, with its price tag of €5,5million, becomes the biggest order in the company's history.

1998

Mr Ernst Kirchhoff takes over the management of Pillard Feuerungen GmbH. Through the establishment of a new sales division for boiler

firing product line, the company extends its market position successfully. Activities for this product are increased and significantly intensified.

1993

Various production and warehouse facilities are concentrated in Taunusstein-Bleidenstadt.

1989

The ROTAFLAM ® rotary kiln burner is registered for a patent. In the following years it is continuously further developed to suit the needs of

customers and the market in general. Today there are more than 800 ROTAFLAM ® burners in operation worldwide.

1982

Pillard Feuerungen GmbH celebrates its silver jubilee. By this time, the company delivered more than 700 units of rotary kiln burners alone.

1979

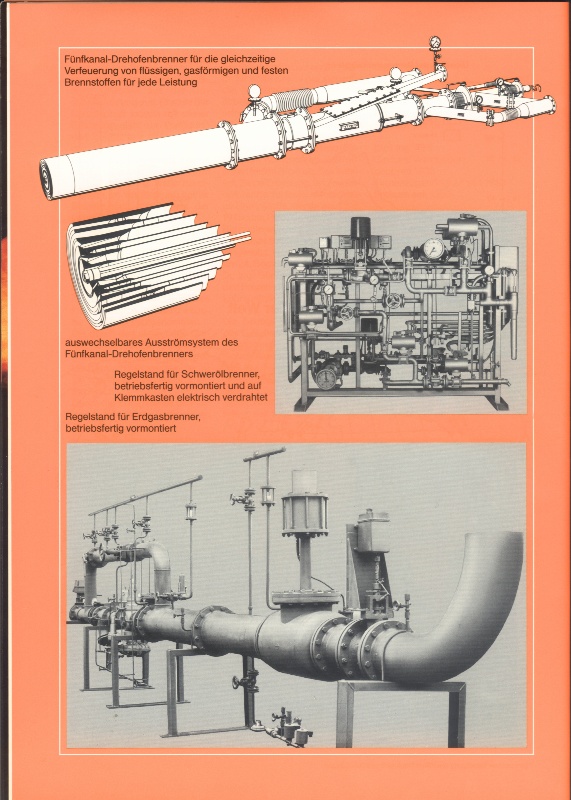

Being a technological market leader is our highest priority. Our product portfolio is widened to enable the use of practically any kind of fuel for

industrial combustion. Based on this, the company decids to change its name to “Pillard Feuerungen GmbH”. Because of the energy crisis that resulted in

sharply higher gas and oil prices, the industry starts to switch back to coal. Dr. Eckelmann develops the three-channel-burner for pulverized, liquid and gaseous fuels.

His invention is submitted for a patent on February 15th. Following a serious car accident, Dr Eckelmann dies on 24.09.1981.

1972

Sales are going up. Relocation is necessary. The company relocates to Taunusstein-Hahn, 12 km north of Wiesbaden.

1965

In the mid 60s, ever more companies switch from coal to oil. In the region of Beckum – Erwitte – Paderborn many small cement factories opted for oil burners.

Pillard receives nearly all contracts. The number of rotary kiln burners put in operation leads to an impressive reference list and at the same time provides

valuable experience to Pillard. This competitive advantage is fully exploited to strengthen the market position of the company and also to (further) develop the

application of natural gas and coal powder.

1963

Dr. Eckelmann is appointed as second in charge of the company. Three years later Mr Louis resigns for health reasons, but continues to provide consulting

services. Dr. Eckelmann takes full control of the company. In July 1963, Pillard is awarded a major contract by Buderus in Wetzlar to deliver rotary kiln burners and

additional equipment. In spite of the very short delivery deadline, the order was filled successfully. From here on, Pillard is acknowledged as a reliable company in

the cement, clay and lime industry having good technical products. By this time, the company has 18 employees.

1957

The founding documents for ‘Pillard Ölfeuerung GmbH' are signed in Wiesbaden on the 23rd of May. Entry in the commercial registry followed on the 28th of September.

The first general manager and shortly thereafter a partner in the business was Mr Rene Louis. With a small group of employees the company is operated successfully in

the often difficult initial years. At this time the product range consists mainly of heavy oil burners for various branches of industry. Pillard delivers the first heavy

oil burner with a 2-3% primary air intake and commissions it successfully. Mr. Louis develops the two-channel-burner, Type VR, for various fuels which sets the technical

standard for a long time.

Abdeckbrenner, reduction burner,

Abfall, waste,

Abfallaufbereitung, refuse recycling,

Abfallbeseitigung, waste disposal,

Abfallbrennstoff, waste fuel,

Abfallverbrennungsanlage, waste incineration plant,

Abfallverwertung, waste recovery,

Abgasgeblaese, exhaust gas fan,

Abhitze, waste heat,

Abhitzeverwertung, waste heat utilization,

Aktivkohle, activated carbon,

Aktivkoks, activated coke,

Altoel, waste oil,

Anfahrbrenner, start-up burner,

Anfahrbrennstoff, start fuel,

Anfahrbrennstoffmenge, start fuel flow rate,

Anfahrdrehmoment, starting torque,

Anfahrflamme, start fuel flame,

Angereicherte Luft, enriched air,

Anheizbetrieb, warm-up operation,

Anthrazitkohle, anthracite,

Armgas, Schwachgas, lean gas,

Aufbereitungsstation, preparation unit,

Aufheizbrenner, start-up burner,

Aufheizzeit, warming-up period,

Ausstroemsystem, burner tip,

Axialkanal, axial circuit,

Axialkoerper, axial body,

Axiallager, axial bearing,

Axialring, axial ring,

Blaehschiefer, expanded shale,

Blaehton, expanded clay,

Bodenheizschlange, bottom heating coil,

Brenner, burner,

Brennerausruestung, burner equipment,

Brennerbedienungsstand, burner valve train,

Brennergehaeuse, burner casing,

Brennergruppe, multiple burners,

Brennerkopf, burner head,

Brennerkopfmutter, burner head nut,

Brennerlanze, torch,

Brennerleistung, burner input rate,

Brennerstein, burner quarl,

Brennertraeger, burner carriage,

Brennerwagen, burner trolley,

Brennkammer, combustion chamber,

Brennkammerbrenner, burner for combustion chamber,

Brennkammergehaeuse, casing of hot gas generator,

Brennstoff, fuel,

Brennstoffmenge, fuel rate,

Brennstoffstaub, pulverized fuel,

Brennstoffstufung, fuel staging,

Brennstoffverbrauch, fuel consumption,

Brennstoffversorgung, fuel supply,

Brennstoffzufuhr, fuel feed,

Deponiegas, landfill gas,

Differenzdruckanzeiger, differential pressure indicator,

Differenzdruckmanometer, differential pressure gauge,

Differenzdruckregler, differential pressure controller,

Differenzdruckschalter, differential pressure switch,

Dolomit, dolomite,

Doppelabsperrkombination, double quick shut-off valve,

Dosierbehaelter, dosing bin,

Dosierschnecke, dosing screw,

Drallkanal, swirl circuit,

Drallkoerper, atomiser,

Drallschaufel, swirler blade,

Drehofen, rotary kiln,

Drehofenbrenner, rotary kiln burner,

Drehofenbrennergehaeuse, casing of rotary kiln burner,

Drosselklappe, throttle flap,

Druckbegrenzungsventil, pressure relief valve,

Druckbehaelter, pressure vessel,

Druckfilter, pressure filter,

Druckmessumformer, pressure transmitter,

Druckreduzierstation, pressure reduzing station,

Druckregelventil, pressure control valve,

Druckwirbelschicht, pressurized fluidized bed,

Druckzerstaeuber, pressure atomizer,

Duesenstock, atomiser gun,

Einlaufmessduese, measuring nozzle,

Eisenerz, iron ore,

Entstaubung, dust removal,

Entwaesserung, dehydratation,

Entwaesserungshahn, drain cock,

Exzenterschneckenpumpe, eccentric screw pump,

Feuerbestaendig, flame proof,

Feuerfestmaterial, refractory material,

Feuergefaehrlich, flammable,

Feuerleichtstein, chamotte light weight brick,

Feuerungsanlage, firing system,

Feuerungsausruestung, firing equipment,

Feuerungsautomat, combustion control unit,

Filterstation, filtering station,

Flammenfuehler, flame sensor,

Flammenstabilisator, flame stabilizer,

Flammenueberwachungseinrichtung, flame safeguard,

Fluessigbrennstoff, liquid fuel,

Fluessiggas, liqufied petroleum gas,

Foerderluft, conveying air,

Fuellstandsanzeiger, level indicator,

Fuellstandsgrenzschalter, level limit switch,

Fuellstandsmesser, level meter,

Funktionspruefung, operational check,

Gasdrallkoerper, gas swirler,

Gasdruckregler, gas pressure controller,

Gasdruckwaechter, gas pressure detector,

Gasduesenstock, gas gun,

Gasfoermiger Brennstoff, gaseous fuel,

Gaskuehlgeraet, Gaskuehler, gas cooler,

Gasuebergabestation, gas transfer station,

Gaswarngeraet, gas leakage detector,

Gaszusammensetzung, gas composition,

Geblaesebrenner, forced draught burner,

Geblaesegehaeuse, fan casing,

Generatorgas, producer gas,

Getaktete Feuerung, pulse firing,

Gichtgas, blast furnace gas,

Gips, gypsum,

Gipswerk, gypsum manufacturing plant,

Glashuettenwerk, glass making plant,

Grubengas, pit gas,

Handzuendbrenner, torch,

Hauptbrennstoff, main fuel,

Hauptbrennstoffzufuhr, main fuel supply,

Hauptflamme, main flame,

Heissdampf, superheated steam,

Heissgas, hot gas,

Heissgasschieber, hot gas slide valve,

Heizbegleitleitung, tracing line,

Heizelement, heating element,

Heizflaeche, heating surface,

Heizkabel, heating cable,

Heizkerze, Heizwiderstand, heating resistor,

Heizleistung, heating capacity,

Heizoel, fuel oil,

Heizschlange, heating coil,

Heizung, heating,

Heizwert, calorific value,

Heizwertmessgeraet, calorimeter,

Hersteller, manufacturer,

Hitzebestaendig, heat-resistant,

Hochofen, blast furnace,

Hochofenschlacke, blast-furnace slag,

Hochofenzement, blast furnace cement,

Hochspannungszuender, high tension ignitor,

Hochtemperaturanlage, high temperature equipment,

Holzkohle, lignite,

Jalousieklappe, shutter flap,

Kalium, potassium,

Kalk, lime,

Kalkstein, limestone,

Kalkwerk, lime manufacturing plant,

Kalzinationsbrenner, calcination burner,

Kanalbrenner, induct burner,

Kesselbrenner, boiler burner,

Klaerschlamm, sewage sludge,

Kohle, coal,

Kohlendioxid, carbon dioxide,

Kohlenmonoxid, carbon monoxide,

Kohlenstaub, pulverised coal,

Kohlenstaubdosiereinrichtung, pulverised coal dosing device,

Kohlenstoffstahl, carbon steel,

Kohlezufuhr, coal feed,

Koks, coke,

Koksofengas, coke oven gas,

Kolbendruckregler, piston pressure controller,

Kraftwerk, power station,

Kreide, chalk,

Kugelhahn, ball valve,

Leichtoelpumpe, diesel oil pump,

Leichtoel, diesel oil ,

Leichtoelzuendbrenner, diesel oil torch,

Luftdrallkoerper, air swirler,

Magnesit, magnesite,

Magnesitstein, magnesite brick,

Mantelrohr, jacket tube,

Muellverbrennung, garbage incineration,

Muellverbrennungskessel, garbage incineration boiler,

Muellverbrennungskraftwerk, garbage incineration power station,

Muellverbrennungsofen, incinerator,

Ofenfutter, kiln lining,

Ofenkopf, kiln hood,

Ofenmantel, kiln shell,

oelduesenstock, oil atomiser gun,

oelmengenzaehler, oil flow meter,

oelschiefer, oil shale,

Petrolkoks, petcoke,

Pilot(zuend)brenner, pilot burner,

Primaerluftventilator, primary air fan,

Prozessgasaufheizung, process gas heating,

Pruefbrenner, check burner,

Pumpstation, pump station,

Quarzsand, silica sand,

Rauchgas, flue gas,

Rauchgasmessung, flue gas measurement,

Rauchgasrueckfuehrung, flue gas recirculation,

Rohkohle, raw coal,

Rohoel, crude oil,

Rostfeuerung, grate burner,

Rueckziehvorrichtung, pull-back device,

Schwachgas, Armgas, lean gas,

Schwachgasbrenner, lean gas burner,

Schwefel, sulphur,

Schwefeldioxid, sulphur dioxide,

Sicherheitsabblaseventil, safety blow-off valve,

Sicherheitsabsperrventil, safety shut-off valve,

Steine und Erden - Industrie, non-metallic industry,

Steinkohle, bituminous coal,

Steinkohleteeroel, coal-tar oil,

Stufenbrennstoff, staging fuel,

Stufenluft, staging air,

Stuetzbrenner, supporting burner,

Stuetzbrennstoff, supporting fuel,

Stuetzkonstruktion, supporting construction,

Temperaturmessumformer, temperature transmitter,

Temperaturregler, temperature control device,

Tonerde, alumina,

Tonerdezement, aluminous cement,

Trocknungsanlage, drying equipment,

Trommeltrockner, rotary drier,

Tunnelofenbrenner, burner for tunnel kiln,

Turbinenradzaehler, turbine type flow meter,

Verbrennungsluft, combustion air,

Verbrennungsluftgeblaese, combustion air fan,

Verbundregelung, coupled control device,

Vorwaermbrenner, pre-heat burner,

Vorwaermer, preheater,

Vorwaermstation, preheating station,

Waermetauscher, heat exchanger,

Waermetraegeroel, thermal oil,

Wirbelschichtfeuerung, fluidized bed combustor,

Wirbelschichtkessel, fluidized bed boiler,

Wirkdruckgeber, differential pressure transmitter,

Wirkungsgrad, efficiency,

Zementwerk, cement manufacturing plant,

Zentralluftkanal, central air circuit,

Zerstaeubungsdampf, atomising steam,

Zerstaeubungsluft, atomising air,

Zuendbrenner, ignition burner,

Zuendbrenner mit Abschaltung, alternating pilot,

Zuendflamme, pilot flame,

Zuendgas, ignition gas,

Zuendlanze, lighting torch,

Zuendtransformator, ignition transformer,